What is Tornado and what is it for?

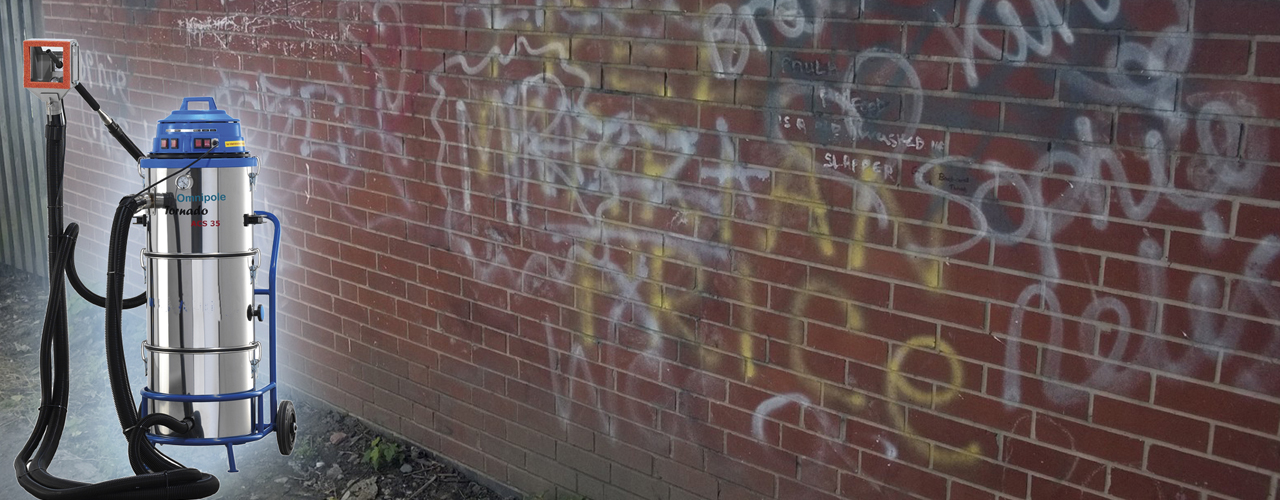

The Tornado ACS cleaning machine is based on a unique worldwide patented low pressure blasting procedure that works neither with high pressure, water nor chemicals. The Tornado ACS cleaning equipment is designed as a mobile and compact device no bigger than a conventional industrial pressure washer. This technology is not comparable with a high pressure cleaner or dry ice blasting.

The combination of units contains a generator for negative pressure with an appropriate filtering cartridge and dust separation as well as the appropriate containers for the granulate. The jet cap, the jet lance and the hose package are further components of the system.

Functioning cleaning equipment

After switching on the negative pressure generator, a negative pressure of approx.170 mbar is produced in the jet cap. The cap is placed on the working surface and adheres on it due to the negative pressure. By inserting the jet lance into the jet cap the cycle is closed. The blast medium is sucked in by the lance and accelerates to more than 400 km/h. With this speed the jet material impinges on the surface, which can be purified, roughened up or cleaned of layers according to requirements.This process can be controlled optimally by the user through vision panels. After impinging the surface the blast medium is sucked off immediately together with the removed particles. Inside of the device dirt particles are separated from granules through a filtering system. Because of that cycle the device system has got a minimum granulate consumption. Depending on the granulate it can be reused about 70 - 100 times in the cycle.

Because of the closed cycle the system has a very low noise level (75 decibel), so it doesn´t operate louder than a customary vacuum cleaner.

Face capacity:

The area coverage of the cleaning machine is depending on the application 2.0 - 4.0 sqm / h for very light applications, the performance is also above, for example, graffiti to be removed on clinker facades or in the dirt removal on rough plaster. Also listed facades can be cleaned very well.

Applications cleaning equipment:

The unique cleaning solution is primarily used for the following applications:- graffiti removal on clinker, natural stone, plaster and EIFS-systems

- graffiti removal on listed facades

- facade cleaning

- floor cleaning

- saltpeter- and limestone removal

- rust removal from metal

- fire damage restoration in closed rooms

- stripping and lacquer removal from surfaces

- restoration

Pros of the system:

- environmentally friendly (cleaning without high pressure, water and chemicals)

- cleaning is done in a closed circuit

- up to 100 times reuse of the blasting material

- just a normal power supply required

- low noise (no compressor)

- transport possible in any vehicle

- short assembly and disassembly times (max. 5 min)

- no protective clothing required

- low purchase costs

- easy and simple handling

- fast amortization of the cleaning equipment